About Lab

IIT Kanpur’s central cryogenic facility houses a Liquid nitrogen and Liquid helium plant. These plants supply cryogenic fluids to support a large number of experiments in various departments, within the Institute. Liquefaction of Helium started in IIT Kanpur plant during the year 1965.

The present liquid Helium plant is a Linde – Model 1610 Liquefier.(Since - 2009)

In Brief operating Principle of the Plant In operation, helium gas is compressed and delivered to the liquefier module at approximately 16.5 bar (240 psig).

The gas is cooled in the liquefier by:

- Liquid nitrogen when the precooler is used

- Heat transfer in the main Heat exchanger

- Isentropic work extraction in the two expansion engines

- Isenthalpic expansion in the Joule-Thomson value

The integral, automatic, freeze out purifier in the Model 1610 Liquefier module allows operation using helium gas with up to 10% air impurities with minimal inlet pressure of 34.5 bar (500 psig). The system purifies by condensing and/or freezing out the impurities then by automatically discharging them to the atmosphere. Refrigeration is provided by cold helium gas from the liquefier.

The present liquid Nitrogen plant is a Linde – Model LINIT-25 Liquefier.(Since-2015)

In Brief operating Principle of the Plant

- Compression-Atmospheric air is filtered and compressed within oil lubricated screw compressor at 10bar

- Purification- Inlet filters and a coalescer remove any water and oil condensate left after the buffe

- Regeneration- Regenerated using a low pressure stream of clean waste gas from the cold box

- Distillation- liquid nitrogen cascades down the column it collects oxygen from the air vapour rising up the column. At the top of the column the rising vapour has lost its oxygen and become pure nitrogen

- Refrigeration- High-pressure process air from the heat exchanger drives the turbine and becomes cooled and expanded.

- Liquid Nitrogen product- The sump pressure is set to be about 1-2 bar higher than the external liquid storage tank. The Liquid is then transferred to the LN LP sump which is set to be about 0.5 bar higher than the LIN tank

Information

- Faculty Incharge: Prof. Satyajit Banerjee

-

Former Conveners

(1) Prof. R.K.Ray

(2) Prof. T.M.Srinivasan

(3) Prof. A.K.Majumdar

(4) Prof. O.P.Katiyal

(5) Prof. K.P.Rajeev

(6) Prof. R.C.Budhani

(7) Prof. Anjan Kumar Gupta - Lab Incharge: Mr. C.Rajan and Mr. Pooran Chandra Joshi

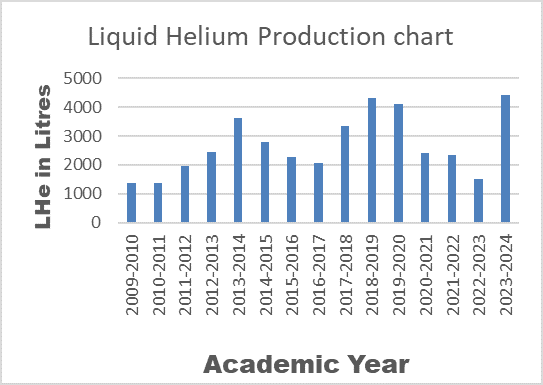

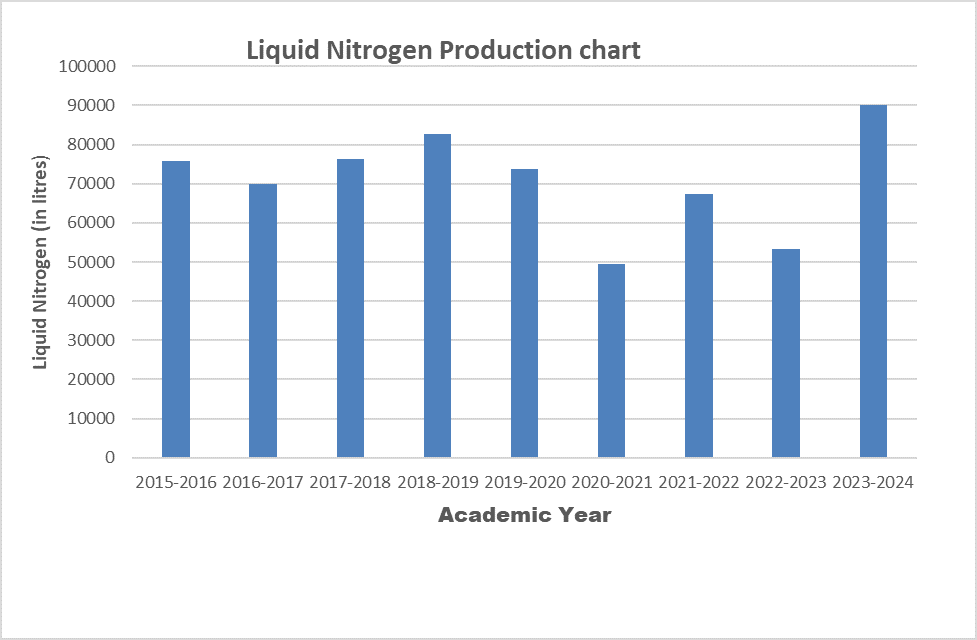

Statistics

Amount of Liquid Produced

From 2009 to till Sep.2024

- Liquid Helium – 41,344.94 Litres

From 2015 to till Sep.2024

- Liquid Nitrogen – 6,71,907 Litres

Average yearly production

- Liquid Helium - 2756 Litres/year

Average yearly production

- Liquid Nitrogen – 70,717 Litres/year

List of Users till Sep-2024

Internal users: Aero, ACMS, BSBE, Chemistry, Chemical, MS/ME, Physics)~120 users

External users: IIPR, HBTU, CSJMU, Rajhospital, Skin Essence, Abhigyan Traders, Adorable engineering etc

Download Forms

Form LN2 & LHe (form related to payment for using the central cryogenics facility) : Download

For enquiries for cryogens

contact: 0512-679-7673/7266

Email Ids- This email address is being protected from spambots. You need JavaScript enabled to view it.

, This email address is being protected from spambots. You need JavaScript enabled to view it.